Download this tutorial for printing.

More Tutorials from Fine Folly -

Click

Here

Devardi Glass And The Hothead Torch

.•:*:•. Tutorial Series .•:*:•.

… HOW TO MAKE ROUND BEADS …

Using A Bead Roller

TUTORIAL OVERVIEW…

In this tutorial you will learn to make round beads using Devardi glass, a tool

and a Graphite

Bead Roller. A Graphite Bead Roller is very useful for shaping stiff glass and

to help your

bead come to round sooner. The longer the glass is in the flame the more stress

that is

placed on it, so a method that shapes glass effectively and with the least

amount of time

and effort is of value.

In some cases we need to shape a particular glass without bringing it to a

molten state

because of impending devit if it is overheated. The other thing to realize is

that as Devardi

glass gets close to devit stage in the flame it often starts to get stiff. As a

side note, with

some of these glass types you can end up with an interesting matt finish when it

has

reached the devit stage. If you push it beyond devit, sometimes it results in a

slick finish

again…

you just have to experiment.

Within the same glass type (Opaque, Semi Opaque and Transparent) you will find

some

works stiff in the flame and some melts easily. This tutorial will teach you to

make round

beads with both types of glass. Actually, I find it quicker to use a Bead Roller

for soft glass

too, because it leaves me more time to decorate and puts less heat stress on the

glass.

Getting your first Graphite Bead Roller can be a bit expensive, but it’s worth

it in the time

and frustration it can save you. They come in nearly endless shapes too.

Because of these considerations I have turned more to the Japanese style of

shaping beads

than the American way. The Japanese will use a tool right from the start,

shaping and

rounding and cooling in the process. If you get the chance, be sure to watch a

Japanese

lampworking video. It can be eye opening to see a different way of handling

glass.

Let’s talk briefly about Devardi glass in general before we begin.

Devardi offers a huge

array of colors at fabulous prices. You get intense, color saturated glass that

is hand-pulled.

The hand-pulling means that rods will come in many thicknesses, some to thick to

use

directly on a mandrel.

When you want to use a thick rod, thoroughly preheat the end of it in your Rod

Warmer and

then pull thick stringer (to use like a thin rod). We offer a Tutorial on

pulling stringer if you

need to learn how, and it’s not hard once you get the knack.

If you don’t want to pull your own stringer, then buying ready-made Devardi

Stringer is a

great option. And if you don’t have a Rod Warmer, buying your glass as stringer

instead

of rods is REALLY a good option, because it will keep you from dealing with

shock and

shattering.

Some colors will hold their coiled-on shape on the mandrel no matter how long

you heat

them in the flame. In fact it can stay put until you bring it to a state of

devit and then to

blistering in the flame. This makes using a tool and a Graphite Roller an

important part of

working it. It also makes for promising sculptural use, but that’s a Tutorial

for another day…

So getting back to the subject…

when you wind a stiff variety on the mandrel and heat it, it

will glow but not merge, so you should use a flat tool to touch and gently press

the coils

together and shape the edges into round, and then use a Graphite Bead Roller for

the final

shaping. After I harangue you on the importance of a Rod Warmer, the following

two pages

offer some soft and stiff glass ‘theory’ that will go into more detail on

shaping before we

begin the actual tutorial.

And on the subject of devit, page 16 of this Tutorial has some neat

information on

preventing devit using Clear Frit Powder as a thin encasing layer.

.•:*:•. ON THE IMPORTANCE OF A ROD WARMER .•:*:•.

Using a Rod Warmer to preheat Devardi glass rods makes all the difference in the

world in

preparing them for the flame, so if you don’t have one, I STRONGLY encourage you

to get

a Rod Warmer. They are not that expensive and they are available from Devardi or

can be

purchased online from Beauty Supply sites (they are called Ceramic Heater

Stoves).

A Rod Warmer reaches 800-900 degrees, so you will rarely ever experience shock

or

shattering if you use one. Some people use a small Teflon coated Grill or

Hotplate

successfully by spending the extra time to make sure the rod is heated slowly in

the flame at

the start, but these don’t come near the temperature of a Rod Warmer.

You can take the time to wave and roll your cold rod in the high, back-end of

the flame to

warm it, and then ever-so-slowly bring it forward, rolling and heating it until

you can bring it

into the actual working area of the flame, but most people don’t have the time

or the

patience to do this successfully on each rod. And it’s really not cost effective

to spend your

time this way either. Even after doing this some people still experience shock

or shattering,

despite their best efforts to adequately pre-warm rods.

About my set-up…

As you can see in the picture above, I use a medium-sized nut can

(from Walmart) turned upside down to rest the ends of the rods on. It is just

the right height

and width. The Rod Warmer gets very hot, so I wrap a piece of Fiber Blanket

around the

cord at the back to act as a heat shield between the Rod Warmer and the cord

because I

have the Rod Warmer in the back corner of my worktable. Ceramic tile is behind

it.

Devardi offers an inexpensive steel plate for the inside bottom of the Rod

Warmer. It will

protect the bottom from glass rods that get put back in the Rod Warmer to hot.

They can

stick to the ceramic bottom and sides if you touch them together in a molten

state, so be

sure to roll your rod and cool it before returning it to the Rod Warmer. The top

of the Rod

Warmer makes a great surface to preheat Murrini on before applying them. I have

the

Murrini sitting on a small piece of steel plate, also available from Devardi.

To work Devardi glass with the greatest ease and productivity put your

rods in the Rod

Warmer about 2” to 3” deep. You only want to preheat the rod end, so that you

can hold it

normally and work it in the flame. When you first turn on your Rod Warmer plan

to preheat

your rod(s) for 5 to 10 minutes before you use them. Then, after each use, roll

the tip of the

rod on your marver to shape and cool it before you return it to the Rod Warmer.

A glowing

rod end will stick to the Rod Warmer and to other rods. Keep returning the rod

to the Rod

Warmer so that it is ready for the next use. Cool rods can be put into a hot Rod

Warmer

without shock, and used once they are fully warmed (about 5 minutes on average).

.•:*:•. Time Out For Some Theory .•:*:•.

On Working With The SOFT Variety Of Devardi Glass

One definition of “ Theory” is …a well-substantiated explanation

of some aspect of the natural world…”

If you haven’t made a round bead before, I would encourage you to stop now and

read the

steps to the tutorial and then come back and read this. It will make more sense

then. So

let’s discuss the theory of shaping a bead when using soft Devardi glass.

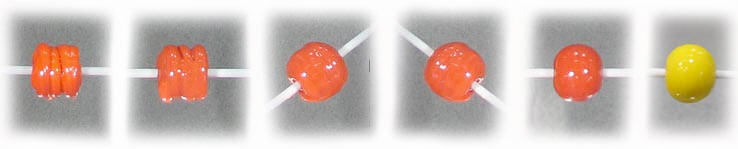

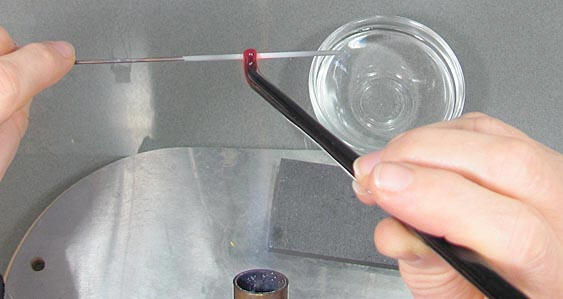

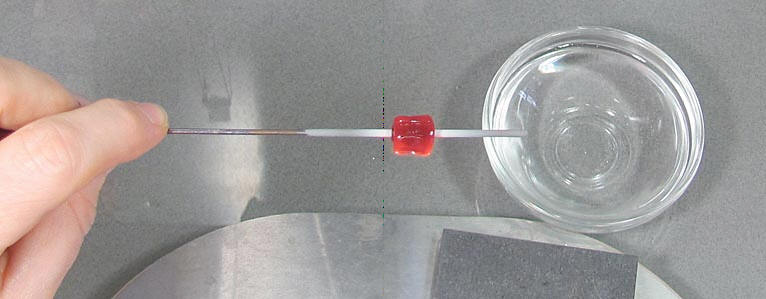

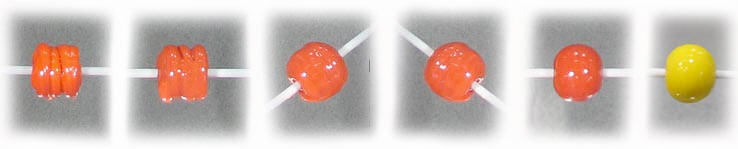

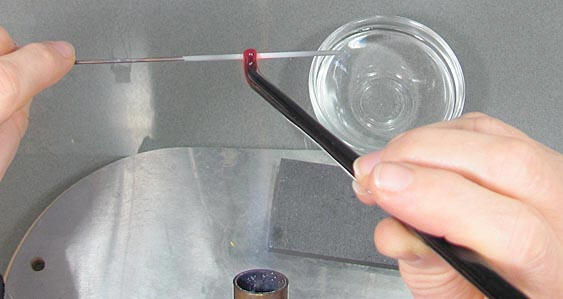

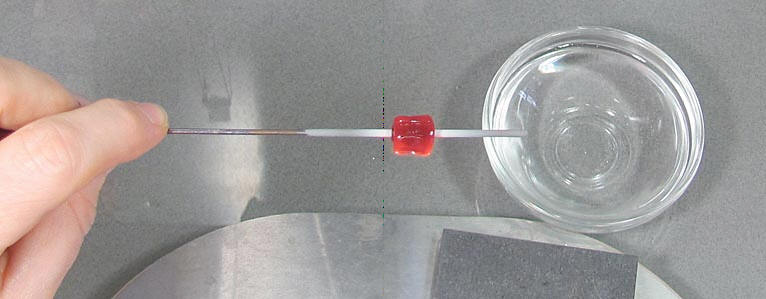

After you have wrapped your barrel (see the picture on the far left above) it’s

time to shape

it round using the flame and your tools as needed.

Soft glass will begin to melt, merge and shape easily in the flame. You can use

your

Graphite Bead Roller right away to form an accurate and consistent shape once

you have

the basic barrel prepared.

As you then decorate your bead, you want to keep the core solid and heat the

surface.

After applying your decoration you can hold the bead below the flame and let the

stream of

heat flow over the top of the bead as you roll your mandrel.

In this way the core can remain fairly solid and hold it’s shape, and the

surface is what gets

softened and smoothed. This is how you melt in details and dots without causing

your bead

to shift and lose round shape. You can also heat one side and then when finished

heat the

other side, so that the side that is NOT being worked helps hold the final

shape.

.•:*:•. Time Out For Some Theory .•:*:•.

On The STIFF Variety of Devardi Glass and Shaping It With Tools

Another definition of “ Theory” …A set of statements or principles

devised to explain a group of facts or phenomena, especially one that

has been repeatedly tested or is widely accepted…”

I want to suggest a simple method to shape stiff glass in the flame in the least

amount of

time, and with the least amount of heat stress on the glass. This method departs

from the

common ‘theory’ of making round beads, and includes pressing and shaping with a

tool, and

then using a Graphite Bead Roller to mold and true up the round shape.

The same ‘rounding’ tendencies hold true for stiff glass as for soft, but on a

lesser scale.

The first difference in working stiff glass is that when you wrap your barrel

shape to begin a

bead you don’t wait for the rounding in the flame. Just jump in and start

shaping with your

tools. It will leave you more time to decorate and save you the frustration of

working and

reworking in the flame to get the shape you want. It will also assist in

producing consistent

sizes of beads more easily, such as in making matched sets. And we can all use

more time

for the decorating and designing end of lampworking.

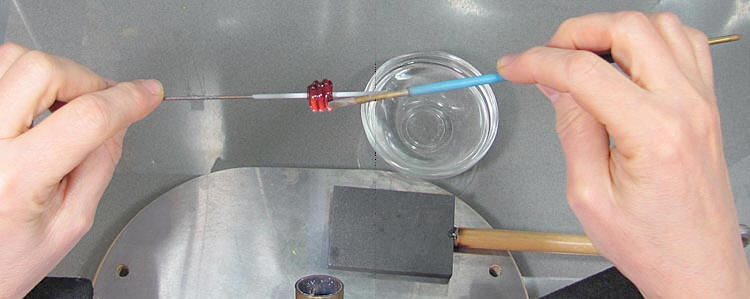

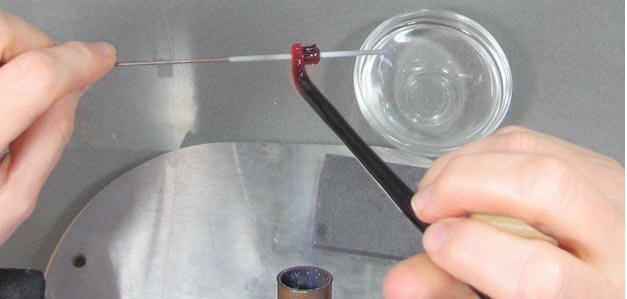

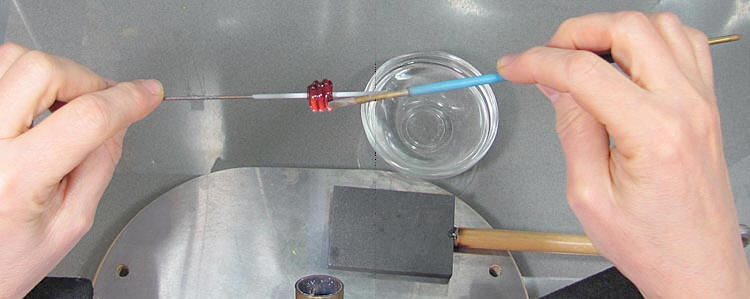

As soon as I have a barrel wound, I prefer a brass tool for shaping because it

can be used

to scoot glass over and touch gaps together easily, and this helps stiff glass

merge quicker.

I also like graphite as a tool because it will smooth rough glass without

sticking (just keep

taking it out of the flame as you work so that you don’t get the graphite so hot

it starts to

stick to the glass). If you buy a graphite rod to sharpen and use, be sure to

set it in a heat-

shielding base to hold it with. Graphite transmits heat right now!

Regardless of what you use, when you touch stiff glass with your tool in the

flame it begins

to flatten and merge, and this is useful to remember and get comfortable with.

And when

you learn to use Graphite Bead Rollers you achieve the shape you want in the

least amount

of time. It’s a win-win situation!

.•:*:•. HOW TO MAKE A ROUND BEAD .•:*:•.

Using A Bead Roller

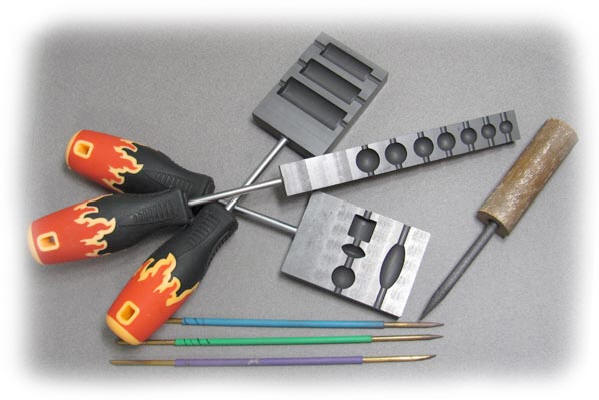

WHAT YOU NEED TO BEGIN…

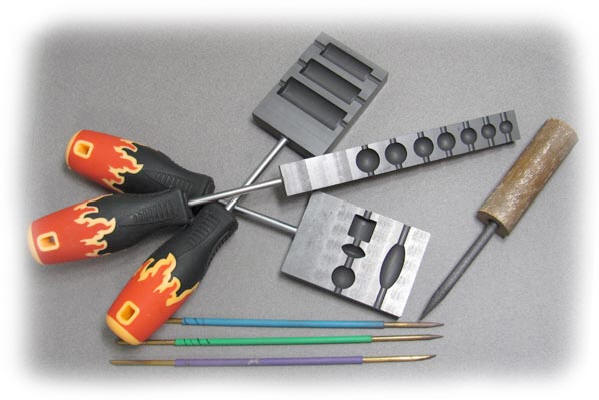

Rod Warmer

Hothead Torch

Mandrel dipped in Bead Release

Brass Tool (or shaping tool of your choice)

Cooling Rack and Marver

Rod or thick Stringer of D165-Opaque High Density Black

Bowl of Distilled Water (Distilled Water helps keep minerals from building up on

your tools)

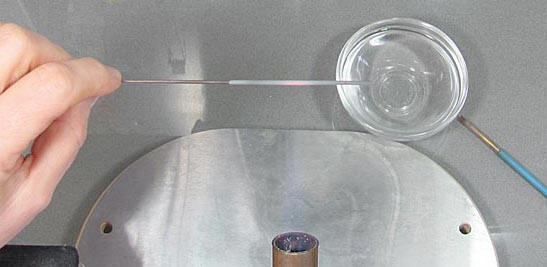

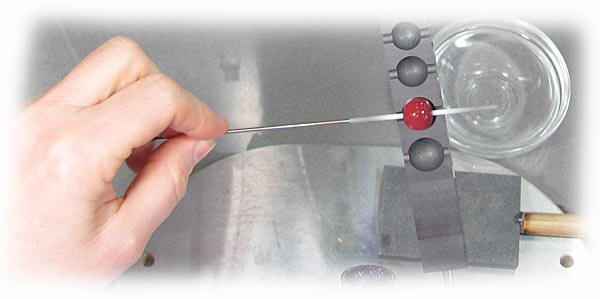

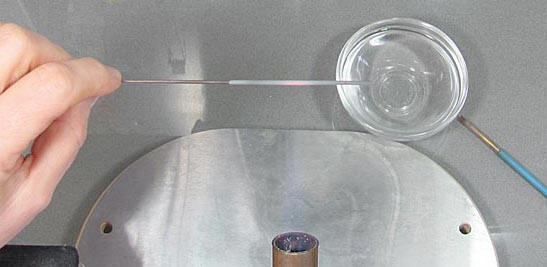

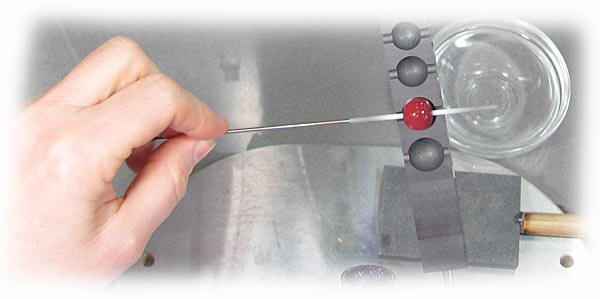

STEP 1. Light your torch and let it warm up a bit. Then adjust it to the

lowest flame

possible. You want your Hothead torch set to the lowest flame it can be without

going out.

You should be able to hold your hands (and work) 2” to 3” from the sides of the

flame when

it is set low enough. As you read through the steps notice how far the rod is

from the torch

head in the pictures. It is about 4” from the torch head to the rod tip in this

first picture.

Spend time rolling and heating the coated end of your mandrel from end to end.

This will

prepare it for the glass and will help prevent air bubbles from developing from

the gas of

uncured/inadequately dried bead release.

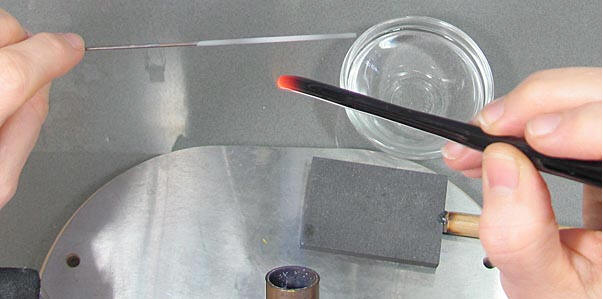

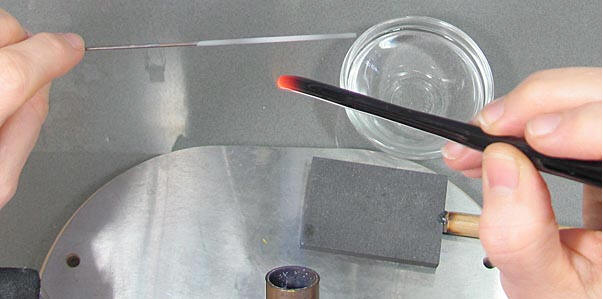

STEP 2. Next, take the pre-warmed rod from the Rod Warmer and dab 2” to

3” of the end in

and out of the flame -about 4” to 5” above the torch. Point the rod end forward

(away from

you) and dab it in and out of the flame a few times to be sure it is fully

pre-warmed. Then

begin to roll about 1” of the tip in the flame, still working about 4” from the

torch head. You’ll

see the sharp edges of the rod begin to soften and then glow when it’s ready to

be worked.

While you do this you should be holding the mandrel farther out in the flame to

keep it warm

as you bring the rod to a glow.

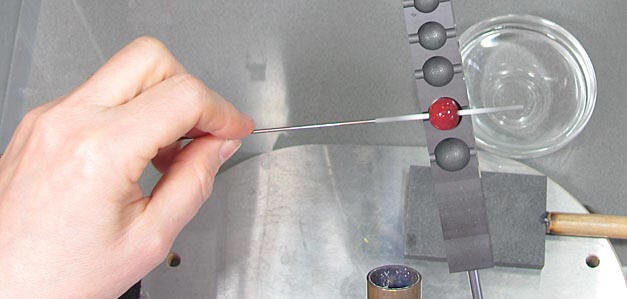

STEP 3. When the end of the rod is glowing, set the tip of it in the

center of your mandrel

and slowly roll the mandrel in the direction that is up and away from you. If

your mandrel is

hot enough it will stick and you can gently pull the glass a bit to stretch the

glass away from

the mandrel. This will give you a thinner length of glass to wrap around the

mandrel. If you

have difficulty using a rod to wrap with, use a stringer, making the same number

of coils and

doing the following steps.

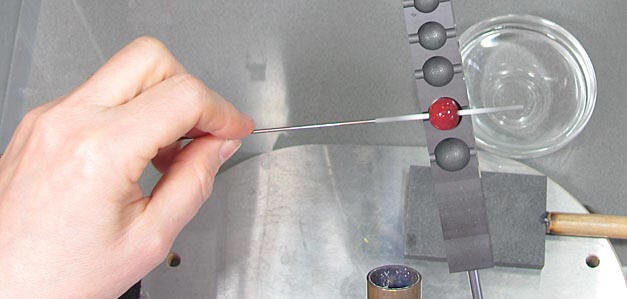

Wrap a complete ring around the mandrel before you start leaning to the right to

make your

next coil. You want to be careful with this first wrap and have it make a full,

even circle. If it

isn’t round and smooth around the mandrel you cannot fix it, and your bead hole

will not be

round. If this happens, flame cut the glass off and put your mandrel in a pot of

water or

wherever you put bad work/mandrels when the bead release breaks, and then start

again.

STEP 4. Continue to wrap with a gently stretched length of glass and move

to the right and

lay your next coil right along the first one. You want to keep the coils the

same thickness

as far as possible.

STEP 5. You are going to make 4 complete coils around the mandrel in this

way. On your

last coil, as you are almost finished with it, stretch the rod away to flame-cut

it. Stretch, roll

your mandrel and wrap the fine strand of glass as you do. In this way you won’t

form an

uneven or big ridge.

STEP 6. As you begin each coil take the time to reheat your rod end to a

soft glow for stiff

glass, or to a molten tip for softer glass like this, and then touch the molten

tip to the far left

side of the barrel and begin to coil again.

STEP 7. Wrap another layer in the same way from left to right. You will

make a total of 3

layers of coils in this way to form your barrel shape before rounding it into a

ball.

STEP 9. Just like before, at the end you need to stretch the glass to a

strand during the last

wrap to make a smooth round finish to the coil. Then flame-cut it off.

Make 3 complete wraps from left to right to create a barrel that is a bit wider

than it is tall.

And if your layers are thin, you may need a 4th row of coils to get a barrel

shape that is

slightly wider than it is square. This shape will give you the right amount of

glass to make a

round bead. If you wrap to tall you get a donut shape bead. If you wrap to wide

you get a

rounded barrel-shape bead, so pay attention to the final shape of your barrel.

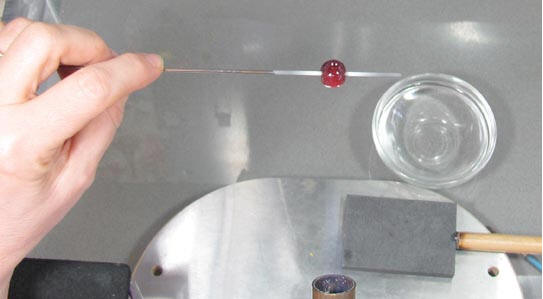

.•:*:•. If you find you have made coils with a large gap in between .•:*:•.

(like the gap between the left and middle coils above) go back and gently heat

and press

the gapped coils together with your tool to merge the coils. The reason to stop

and do this

is because you want to start each wrap on a fairly smooth base so that you don’t

trap air

bubbles. An air bubble can rise and pop open a hole on your bead, or just sit

there on the

surface, showing as a little bubble.

If an air bubble does occur later, heat the bubble to a glow and use sharp

tweezers to

delicately pinch under the bubble and stretch it off (like flame-cutting the

glass at the end of

a wrap) as you roll your mandrel. Then reshape the area you pinched the bubble

off of.

The next page shows the gap in the coils above being closed with a tool.

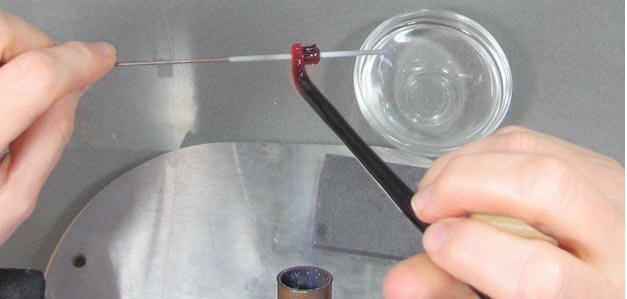

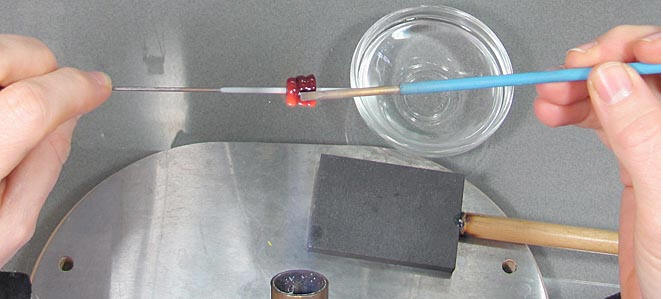

To close gaps, gently heat the coils and

use your tool to scoot them toward each other.

You want to bring the coils you are working on to a gentle glow and then touch

with your

tool over and over. Be sure to cool your tool repeatedly. The metal touching the

glass

helps the glass merge and smooth out. Your bead should be in and above the

flame, about

4” from the head of the torch.

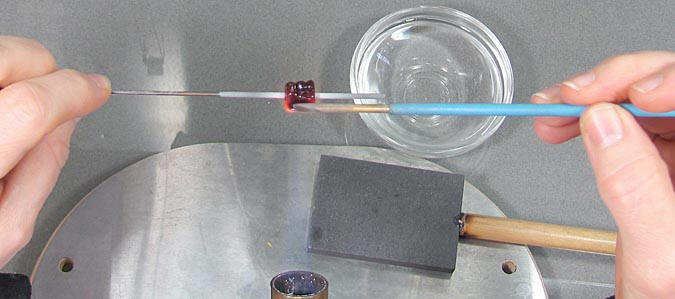

When your bead surface has been smoothed out you are ready to start the next

wrap. You

do not want to lose the barrel shape at this stage, so do not overwork it (or

overheat it and

start it rounding in the flame if it is softer glass). This picture shows the

bead starting to

glow and get to soft and wanting to round -but it still needs one more layer of

coils so it is to

soon to let it go round. Be aware and keep the barrel shape.

Now back to our tutorial steps…

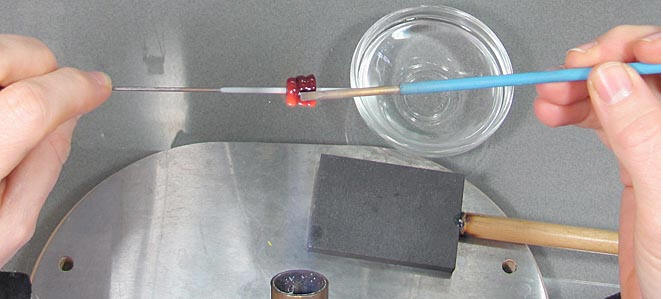

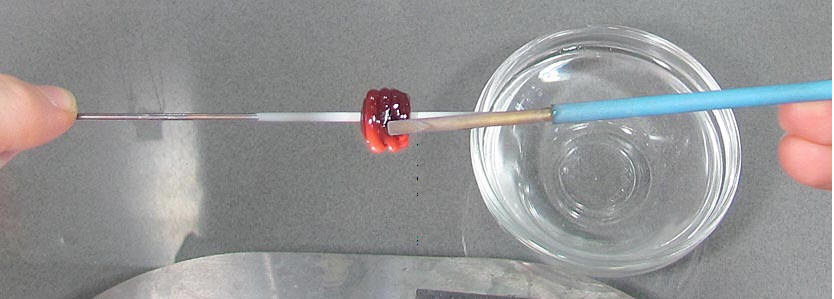

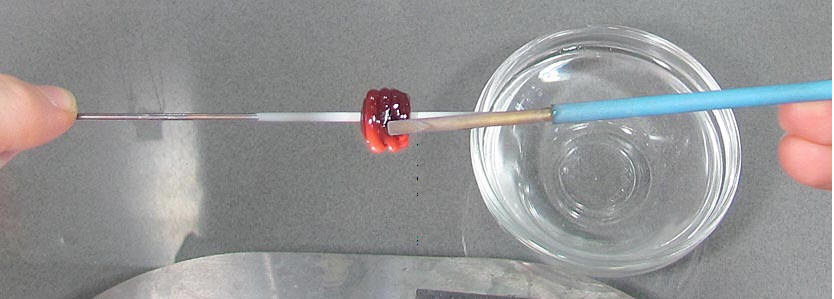

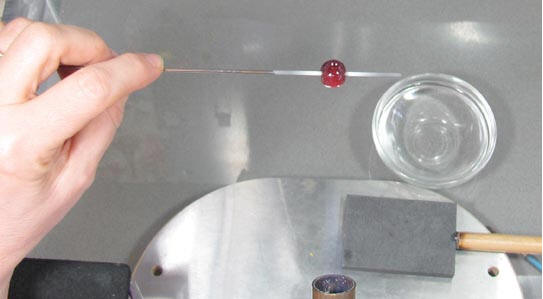

STEP 10. Once you have the barrel made, continue to turn your bead in the

flame and start

to use your flat tool to gently press the right rim of the barrel in toward the

center. This is to

help the side start to become round. Do this all the way around the bead. Don’t

press so

hard that you make a cone shape, just gently press the rim/edge smooth all the

way around.

STEP 11. Gently heat and press the middle coils into one another and then

angle your

mandrel and gently press the left rim all the way around the bead.

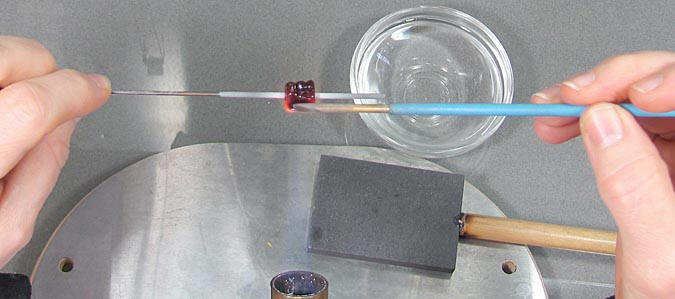

STEP 12. When your left and right rims are softly rounded and your middle

coils are

merged, you should look closely at the glass around the mandrel on both sides of

the bead.

If you have ridges circling the mandrel, gently heat and use your tool to make

them merge

or disappear. Now you are ready to bring the bead to a glow and put it in the

Bead Roller.

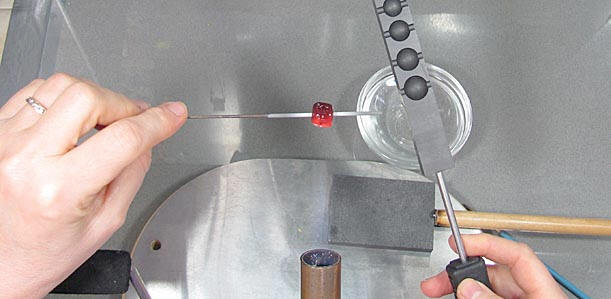

.•:*:•. Time Out For Some Bead Roller Tips .•:*:•.

Graphite has a wonderful slick surface that molten glass glides on. Here are

some general

tips on using a Graphite Bead Roller.

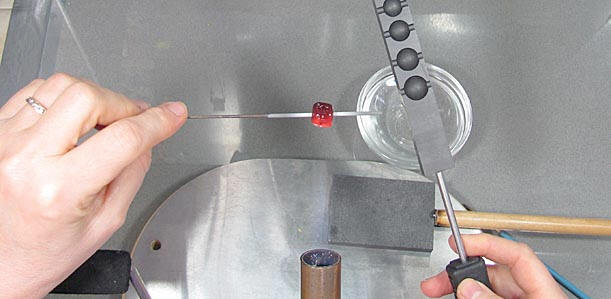

To begin shaping, once your barrel has been rounded up using your tool and the

flame,

you heat the bead to lightly glowing and put it in the hole or cavity that is

just larger than the

bead. Very gently press it against the right side of the Bead Roller cavity to

begin rounding

on that side (and then repeat on the left side). Repeat as needed, but reheat

each time

before using the Bead Roller. After you get the sides in a rounded shape, reheat

and then

roll your bead gently against the bottom of the cavity to bring the center to a

round shape.

When the sides and the center have taken the rounded shape of the Bead Roller,

then I

reheat and gently roll the bottom-center of the bead one last time against the

bottom of the

Bead Roller for a final shaping.

If the bead is smaller than the cavity being used, you can heat and fit it in

stages into the

smaller cavity. When it is rounded it should have a slight clearance all the way

around in

the Bead Roller cavity, or you should use the next larger size hole.

If any given spot needs attention, first heat the side that needs attention,

leaving the other

side firmer so that the cooler side helps hold the round shape you have already

accomplished. Gently heat and press or roll the heated side to get the shape you

want.

When you are happy with the round shape, very gently reheat the entire bead,

rolling it and

slightly flame polishing it before you put it in your bead kiln (or whatever you

use at this

point) to cool the bead slowly – or you are ready to start decorating it!

The Bead Roller shown in this Tutorial is from CGbeads at

www.cgbeads.com but I

think

that Devardi is planning to offer them at some point. CGbeads has videos showing

how to

use the Bead Rollers, and they are worth watching if you plan to get one.

STEP 13. Heat and shape your bead in the Bead Roller as described on the

previous page.

STEP 14. When you are happy with your bead gently reheat it one last time

to slightly

flame polish it if needed, and then decorate it or put it in your Bead Kiln (or

whatever you

use to garage your beads).

Now give yourself a ‘round’ of

congratulations!

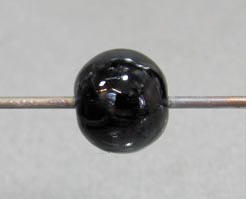

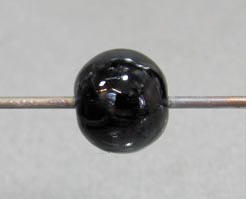

.•:*:•. Opaque High Density Black & Your Hothead Torch .•:*:•.

This has been a long Tutorial, but I want to add one last thing about working

with Opaque

High Density Black on your Hothead Torch. Sometimes you will end up with a

metallic

sheen on your black bead, as you can see in the picture on the top left side.

To remove this sheen, after your bead is annealed and cool, clean it with Tarnex

and then

wash the Tarnex off and dry it. This simple treatment is useful to know,

especially since

black is such a nice base color to work with.

.•:*:•. Round Possibilities.•:*:•.

The froggie’s base bead was made with Transparent Cranberry. Sterling silver

wire was melted on

to make the silver dots on the surface of the bead, like the bracelet on the

first page.

Now that you can make round beads with consistency just think of all the designs

you can

make! You can use frit, draw designs on with stringer, make dots and create

combinations

of design that interest you…

the possibilities are truly endless.

In closing, here are 3 bracelets decorated with frit, stringer work and dots. If

you like their

design feel free to make them up for yourself or to sell. Our tutorials always

allow you to

make and sell any item or pattern shown.

To assist you with frit, stringer and dot work, here are a few pointers (if you

need them).

And realize that there are many ways to work with these applications, so this is

just one

way. Remember to experiment with the colors and techniques that interest you

BEFORE

you jump into a full project. Some glass will hold up in the flame and some

won’t. Some will

fight with it’s neighbor and some works great together. Make test beads and

anneal them

before you create an entire project to avoid frustration and loss of labor and

glass.

To draw with stringer, gently preheat the working area on the bead

surface and the tip

of your stringer, and then set your stringer on the bead – holding it to the

right side of the

flame to begin.

You want to find the place beside the flame that causes your stringer to relax

just enough to

draw with it. Move closer to the flame until you feel the slight ‘give’ start

and then get busy

drawing! When you find this special ‘spot’ near or in the flame you should be

able to put

gentle pressure on the stringer to draw as you like (while it stays stiff in

your hand) yet

glides onto your bead at the tip – not to hot, not to cool!

|

|

|

The Stringer and Dot Bracelet was made using

Opaque Burnt Carrot Orange and both Medium and

Dark Brown for the beads, with Metallic Silvery Black

use for stringer and dot work.

|

|

To make dots, gently preheat the working area on the bead surface, and

then preheat

the tip of your stringer to form a tiny dot on it. Then set the dot on your bead

where you

want it, moving closer to the flame to cut it as you pull the stringer away.

Once you have

applied your dot(s) be sure to reheat the dots in the flame. Heat them enough to

‘seat’ them

on the bead so that they don’t pop off, or have undercut area that can get

hooked on

something.

If your glass stringer is to stiff to form a dot on it’s tip, then heat the tip

and set it on the bead

and flame cut as you pull. In this case, press the stringer to the bead to get

the size dot

base you want, and pull off slowly or quickly to leave the amount of glass you

want in the

dot. Put the dot right back in the flame to round it if you are using a stiff

glass.

You can go back and touch a cool dot with a hot stringer tip to add more glass

to the dot.

|

The Dot Bracelet was made by using

different Devardi transparent colors with effetre dots applied afterward. If

you want a creamy melt to your dots without tool work, Moretti/effetre melts

nicely across Devardi glass. |

|

| |

|

| |

|

|

|

The Frit Bracelet was made using

Semi Opaque Lt. Baby Blue with a 96 COE frit that was melted on and then

raked. The bicone beads were made with Transparent Vibrant Blue.

Frit comes in different COE’s. Typically 96 COE frit is more vibrant in

color, but use it sparingly (use 10% or less compared to the size of your

bead). Devardi is 104 COE. |

| |

|

To use frit, make your bead and then

roll it in the frit of your choice. Put the frit in a large

spoon and hold it under the torch to set your hot bead in, or put it on your

mandrel and roll

your hot bead on it. You can use whatever method you like.

Once you have the amount of frit you want on the bead, press the frit flat with

your tool as

you gently heat it in the flame. Add a layer of clear powdered frit and melt it

in if the frit or

glass is prone to devit. To rake the frit, heat the bead to a gentle glow and

use your pick in

the flame to hook just the surface of the bead’s frit and roll your marver

slowly but steadily

away from you, raking the frit in the flame as you turn. When you have raked all

the way

around, lift the pic and stretch/flame-cut the glass that was hooked off. Put

your pic in cool

water to shatter off any glass that adhered. Gently flame-polish and shape the

bead.

|

|

|

A Note On The Benefit Of Using Clear Frit Powder Between Layers…

Devardi glass likes to be worked cool in the flame. Some colors want to be

heated without

ever getting to molten stage, or they may devit. I have found that after shaping

the bead, if I

roll it in clear frit powder and then melt it in I can then work the color much

hotter in the

flame, and I can stack colors, adding a layer of the clear frit powder between

each stack if

needed. Experiment with this and see how you like it.

The bead below was made with this method. The base is Opaque High Density Black,

with

base dots of SOP Moonstone White, and then dot colors in Transparent Cranberry

and

Cobalt Blue, SOP Lemon Yellow and a Green. I had to press the dots flat and

shape them

because they tended to stiffness, applying clear frit powder with each new

layer.

Finally, I raked the edges of the dots toward a center point, and then used the

blunt end of a

clear stringer to twist them, and applied a dot of Opaque High Density Black on

top. Fun!

.•:*:•. About My Lampworking Set-up .•:*:•.

You might be interested to know what the black bars are in the tutorial

pictures. I use a

‘Creation Station’ for elbow and wrist rests. I find it makes all the difference

in keeping a

steady hand when applying fine detail.

I use bulk propane with my Hothead Torch. I have a long hose that goes through

the wall to

the 5-gallon propane tank. I am careful to thoroughly clear the gas out of the

hose after

each use of the torch. This has stopped the problems I originally had with

spitting and gunk

in the line.

Please note that I show the Hothead Torch in each picture so that you can refer

to the

location of it as you work (especially if you are having a problem with any

given step).

Realize that you are looking down at the torch, so you can’t see what is below

the flame and

what is in it. I try to state where to hold things when it is important to the

step.

These tutorials were made using a Hothead Torch, but any torch can be used.

If you

are on a surface or pre-mixed torch you will need to make adjustment for the

significant

difference in heat that it produces. For example, you will not be able to use

your tools

directly in the flame as you can on a Hothead Torch. You must work to the side

of the flame

with tools. A Hothead Torch is much cooler than other types of torches.

Please feel free to email me at FineFolly@bellsouth.net if you have questions. I

always like

to help if I can!

Annealing Bubbles versus a Fiber Blanket

or a Crockpot of Vermiculite

If you do not have a bead-annealing kiln to put your work in after you finish it

then you

probably use either Fiber Blanket or a crockpot full of Vermiculite, or what are

called

Annealing Bubbles.

I have used each one of them, and for the size beads I tend to make I found that

the

Annealing Bubbles were more effective at slowly cooling my beads. I used to wrap

my

crockpot in a fleece blanket while set on high to let my larger beads cool, and

then turn it off

after a few hours, but that is not recommended and can cause your crockpot to

overheat, as

you can see by the faded paint on the crockpot in the picture above!

But even the Annealing Bubbles are inadequate for all but smaller beads, when it

comes

right down to it. If you continue in lampworking you need an annealing kiln.

Devardi plans to offer a Rod-Warmer sized mini-kiln soon. Look for it as the

least expensive

option to anneal and cool beads. Another option you might like to know about is

The Glass

Hive. They allow you to put a kiln on layaway and take as long as you like to

pay it off, and

that is what I did. You can see their ‘Short Guy’ kiln in the picture above.

It’s a great little

kiln. The Glass Hive is online at

www.theglasshive.com if this interests you.

They

frequently have sales where they reduce the price or pay for the shipping.

To locate Annealing Bubbles, do a search for ‘Annealing Bubbles’ online and find

the best

price for them in the large Tin. They need to be in metal to work best and the

larger Tin lets

you put many beads in it during a work session at the torch. The supplier I got

them from is

www.artcoinc.com